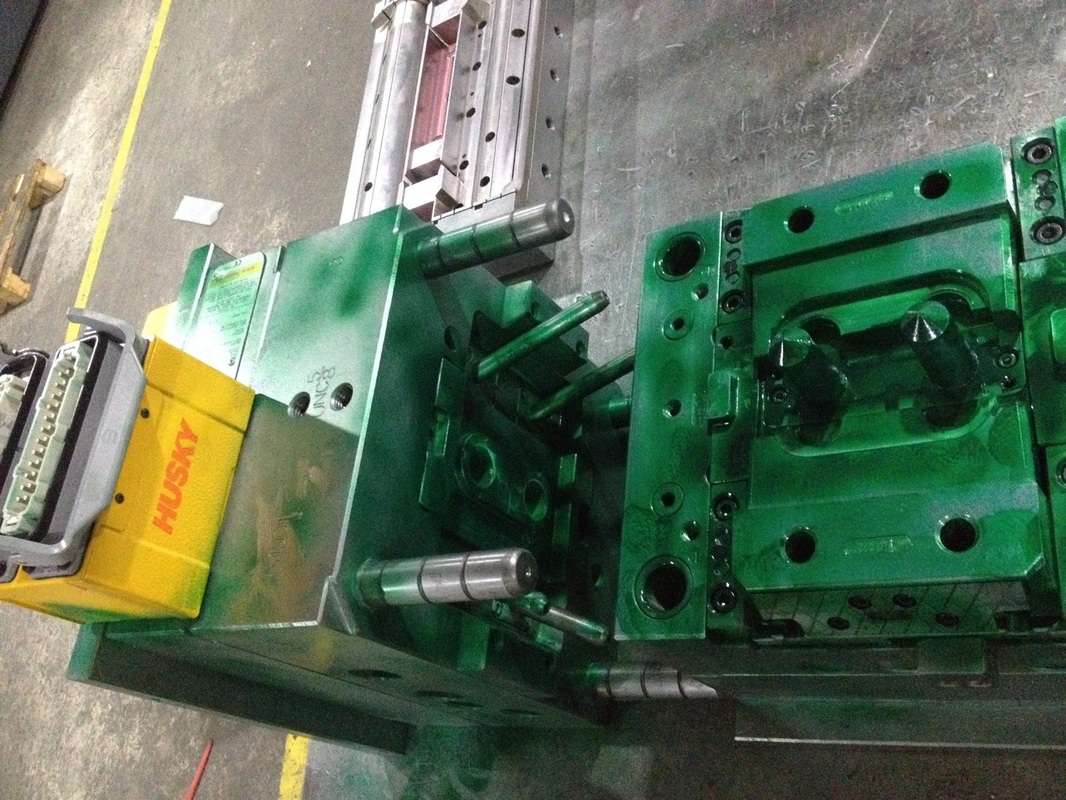

Double Injection in performed on one machine that is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The mold is then automatically rotated and a different type of plastic is injected into the mold from a second nozzle.

Double Injection Molding optimizes co-polymerization of hard and soft materials to create powerful molecular bond. The result is a single part with production and feature advantages. It can be used for a variety of product designs across all industries. It also allows for molding using clear plastics, colored graphics and stylish finishes which improves your product functionality and marketplace value.

Double Injection advantages include:

- Lower unit cost

- Improved part integrity

- Multi-material efficiency

- Higher-quality plastic part fabrication

- Reduced handling and secondary assembly

- Reduces cost and waste associated with assembly defects

- Enhanced tactile and cosmetic product feature

RSS Feed

RSS Feed